The Complete Guide to Lippert Attaching Parts Kits for Double Eye Spring Axles

Transform your trailer's suspension system with professional-grade aftermarket solutions

When it comes to trailer maintenance and upgrades, few components are as critical as your suspension system. Whether you're dealing with worn-out hardware, planning a complete suspension overhaul, or simply want to upgrade to a more robust system, Lippert's Attaching Parts (A/P) Kits for Double Eye Spring Axles offer a comprehensive solution that's designed for both durability and ease of installation.

What Are Attaching Parts Kits?

Attaching Parts Kits are complete hardware solutions designed to connect your trailer's axles to the chassis through the suspension system. These kits include all the necessary components to either upgrade existing suspension systems or replace worn-out parts with high-quality alternatives. Lippert's A/P Kits are specifically engineered for aftermarket applications, meaning they're designed to work with a wide variety of trailer configurations.

Available Kit Configurations

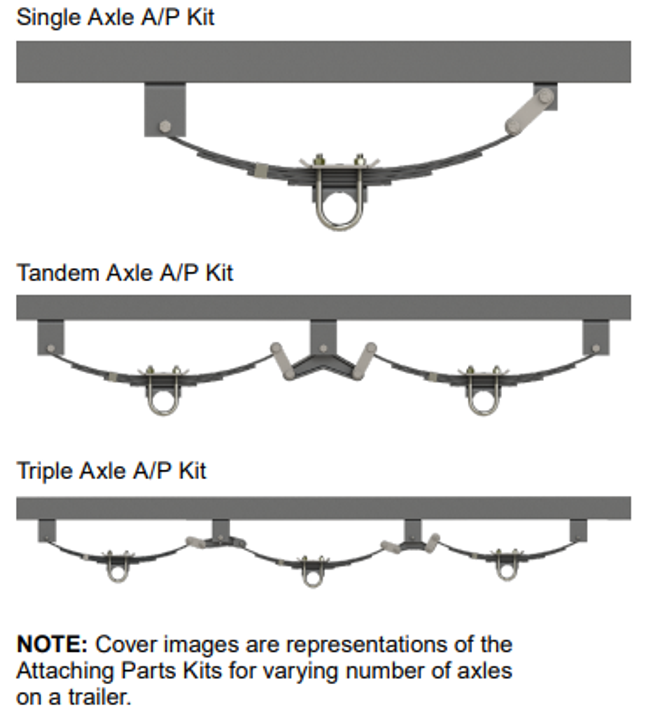

Lippert offers several A/P Kit configurations to match different trailer setups:

Single Axle Kits

- Part #121101: Single Axle A/P Kit with 3 1/8" Link

- Perfect for single-axle trailers requiring reliable, straightforward suspension attachment

Tandem Axle Kits

- Part #121097: Tandem A/P Kit, 33" Axle Spacing, EQ-104

- Part #121098: Tandem A/P Kit, 33" Axle Spacing, EQ-310

- Part #121099: Tandem A/P Kit, 35" Axle Spacing, EQ-E1

Triple Axle Kits

- Part #121100: Triple A/P Kit, 33" Axle Spacing, EQ-104, EQ-105

- Part #126452: Triple A/P Kit, Heavy Duty, EQ-104, EQ-105

Each kit is precisely engineered to match specific axle spacing requirements and load capacities, ensuring optimal performance and safety.

Key Components and Features

Standard Kit Components

Every A/P Kit includes precision-engineered components:

- High-Grade Bolts: 7/16" - 20 x 2 7/8" Grade 5 bolts with black phosphate and oil finish for corrosion resistance

- Locking Nuts: 7/16" - 20 reversible locking nuts for secure fastening

- Shackle Link Assemblies: Various sizes (2.25" to 3.13") depending on application

- Equalizer Assemblies: Featuring nylon or bronze bushings for smooth operation

Heavy-Duty Options

For demanding applications, Lippert offers heavy-duty variants featuring:

- Wet Bolts: Greaseable bolts with integrated lubrication fittings

- Bronze Bushings: Superior wear resistance compared to standard nylon

- Extended Shackle Links: Heavy-duty 3.75" x 1.50" links for increased durability

Installation Advantages

Versatile Mounting Options

These kits accommodate both overslung and underslung axle configurations, making them suitable for a wide range of trailer designs. This flexibility means you can upgrade your suspension system without major modifications to your trailer frame.

Professional-Grade Hardware

The inclusion of serrated bolts ensures maximum resistance to rotation during service, dramatically extending the life of your suspension components. The torque specifications (30-50 ft-lbs for 7/16" hardware) are clearly defined to prevent over-tightening and ensure optimal performance.

Maintenance-Friendly Design

Heavy-duty kits with wet bolts feature grease fittings that allow for regular lubrication, significantly extending component life. The recommended multi-purpose grease (NLGI code GC-LB) ensures proper lubrication in all weather conditions.

Safety and Installation Considerations

Critical Safety Requirements

Lippert emphasizes several critical safety points:

- Professional Support: Always support the trailer per manufacturer's recommendations before working underneath

- Proper Torque: Use calibrated torque wrenches to achieve specified torque values

- Correct Installation: Bolts must be driven (not pulled) into position to properly seat serrations

Installation Best Practices

- Install all bolts from outside-in toward the center of the trailer chassis

- Use steel tube installation tools for bolts with grease fittings

- Ensure spring eyes can rotate freely on non-shouldered bolts

- Position grease fittings at 3 or 9 o'clock for optimal lubrication

Maintenance Requirements

Regular Inspection Schedule

Lippert recommends inspection every 12 months or 36,000 miles, whichever comes first. During inspection:

- Check all nuts for proper torque (30-50 ft-lbs)

- Ensure equalizers are free from debris

- Lubricate wet bolts with appropriate grease

- Inspect bushings for wear or damage

Long-Term Performance

With proper installation and maintenance, these A/P Kits provide years of reliable service. The combination of high-grade materials, precise engineering, and user-friendly design makes them an excellent investment for any trailer owner serious about performance and safety.

Choosing the Right Kit

When selecting an A/P Kit, consider:

- Axle Configuration: Single, tandem, or triple axle setup

- Axle Spacing: 33" or 35" spacing for multi-axle trailers

- Load Requirements: Standard or heavy-duty applications

- Maintenance Preference: Standard nylon bushings or greaseable bronze bushings

Professional Support and Resources

Conclusion

Lippert's Attaching Parts Kits represent a professional-grade solution for trailer suspension needs. Whether you're performing routine maintenance, upgrading to heavy-duty components, or building a custom trailer, these kits provide the reliability, durability, and performance you need.

The combination of high-quality materials, precise engineering, and comprehensive support makes these kits an excellent choice for anyone serious about trailer performance and safety. With proper installation and maintenance, they'll provide years of dependable service, giving you confidence on every journey.

Ready to upgrade your trailer's suspension system? Call us 888-634-9494